7 OUT OF EVERY 10

AMERICAN TRUCKERS

USE ONE BEARING.

NOW IT'S YOUR TURN

American drivers have spoken with their wheels -

and Hyatt is their choice. Fit for all makes. Made to last.

Now available at MaxiPARTS outlets.

Standard features of Hyatt Tapered Roller Bearings include but are not limited to:

- Extremely close roller diameter variation within any assembly

- Superior dimensional and surface finish controls

- Optimum geometry, including roundness, profile and angle

- Crowned rollers and pathways

- Through hardened steel for optimized life

- Super clean steel for rollers and races

- High strength steel cages

- Low vibration levels tested 100%

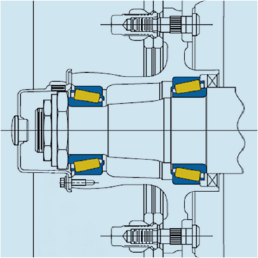

Proper mounting of a bearing is crucial to minimise failures and achieve the longest lifecycle for the product.

Correct dismounting practices is equally important. Follow our simple installation guide to ensure you are using the correct installation methods.

RECOMMENDED WHEEL BEARING ADJUSTMENT

For manually adjusted wheel end assemblies, we have developed a simple procedure to assist.

For pre-adjusted wheel end assemblies, contact the manufacturer for recommended adjusted procedures.

MEASUREMENT ACCURACY CONSIDERATIONS

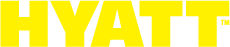

Hyatt tapered roller bearings, with their two part construction consisting of an outer race called a cup and inner race and rollers known as a coneassembly, lend themselves towards solving difficult assembly problems where high load carrying bearings are required. Download our information chart as a reference to measurement accuracy for Hyatt bearings.

BEARING FAILURE CAUSES

Many different types of bearing damage can be prevented with the knowledge of how external influences affect the life of a rolling bearing.

Download our guide as a reference towards understanding the causes and effects of bearing damage.

Adelaide

562 Grand Junction Road, Regency Park SA 5010

Tel 08 8445 8788

Albury

3/115 Catherine Crescent, Lavington NSW 2641

Tel 02 6040 1426

Ballarat

264 Park St W, Delacombe VIC 3356

Tel 03 5335 7305

Bibra Lake

U1/2 Hathor Way, Bibra Lake WA 6163

Tel 08 6499 4699

Bendigo

110 Midland Highway, Epsom VIC 3551

Tel 03 5441 7666

Bunbury

67 McCombe Road, Davenport WA 6230

Tel 08 9707 1599

Burpengary

1 Brewers Street, Burpengary QLD 4505

Tel 07 3888 7755

Darwin

152 Coonawarra Road, Winnellie NT 820

Tel 08 89471627

Campbellfield

2066 Hume Hwy, Campbellfield VIC 3061

Tel 03 9308 0088

Eagle Farm

213 Fison Ave West, Eagle Farm QLD 4009

Tel 07 3624 3900

Geelong

95 Douro Street, North Geelong VIC 3215

Tel 03 5240 5200

Geraldton

94 Anderson Street, Webberton WA 6530

Tel 08 9999 2800

Gladstone

21 Beckinsale St, Gladstone QLD 4680

Tel 07 4839 4000

Ipswich

29 Flint Street, North Ipswich QLD 4305

Tel 07 3281 5550

Lynbrook

Unit 6, 2-8 Northey Road, Lynbrook VIC 3975

Tel 03 9799 7788

Mackay

11 Central Park Drive, Paget QLD 4740

Tel 07 4841 9200

Parkinson

68 Precinct Street, Parkinson QLD 4115

Tel 07 3806 6555

Port Hedland

Unit 1/323 Hematite Drive, Wedgefield WA 6721

Tel 08 9172 4004

Richlands

U1/18 Macgregor Pl, Richlands QLD 4077

Tel 07 3277 5377

Rockhampton

113 Gladstone Road, Allenstown QLD 4700

Tel 07 3320 7290

Sunshine West

2/180 Fairbairn Road, Sunshine West VIC 3020

Tel 03 9316 5999

Sydney

5-7 Memorial Avenue, Ingleburn NSW 2565

Tel 02 9618 6357

Townsville

715 Ingham Road, Bohle QLD 4818

Tel 07 4758 4800

Truganina

22 Efficient Drive, Truganina VIC 3028

Tel 03 8368 1155

Wagga Wagga

150 Hammond Avenue, Wagga Wagga NSW 2650

Tel 02 6921 6044

Warnervale

15 Burnet Road, Warnervale NSW 2259

Tel 02 4394 0066

Welshpool

35 Kewdale Road, Welshpool WA 6106

Tel 08 9356 1599

Wetherill Park

511 Victoria Street, Wetherill Park NSW 2164

Tel 02 9765 4870

Yatala

5 Hovey Road, Yatala QLD 4207

Tel 07 3807 2842

VIC wholesale and HO

22 Efficient Drive, Truganina VIC 3028

Tel 03 9368 7000